Welcome to SP Panels, the worlds

only manufacturer of the full range of galvanised replacements doors for Land

Rover® models.

Our body panels are made with the highest quality materials using the same

technology as used originally to produce accurate and fantastic fitting parts.

The main issues with the original doors fitted to Series and Defender® models is that the steel frames rust out in

front of you. We manufacture all of our doors with hot dipped galvanised frames

as standard to ensure when you buy a door from us, you only need to buy it

once.

All of our doors start from laser

cut blanks, each one is precision cut so each blank is exactly the same. This

level of accuracy is carried on throughout the stages of manufacture to ensure

the final product is as good as, or exceeds original.

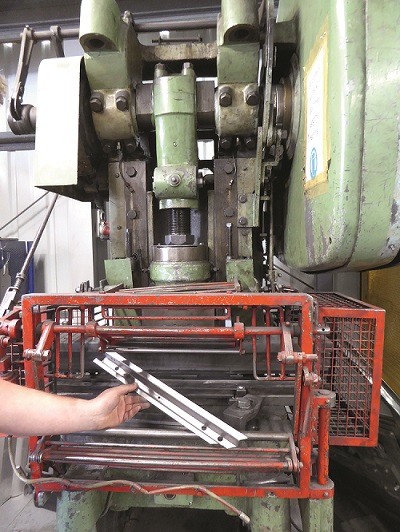

Once each blank is cut, we then

move onto pressing or CNC folding each blank into an actual 3d component. Our

CNC pressbrake enables us to fold each part accurately and the same, each and

every time.

This is where the doors start to

really take shape and start looking familiar!

Most of the pressed components

require backing plates to be attached to them to add to the structural strength

of the part. This forms a hollow sectioned component. The backing plates are

attached using a spot welder as seen below:

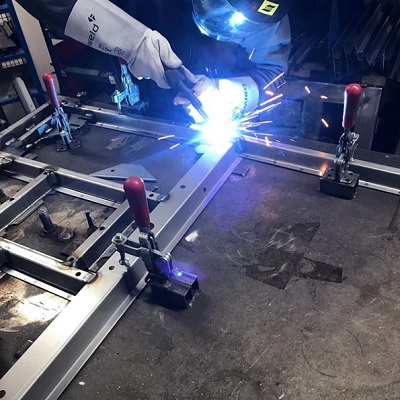

Once each of the individual

components is formed, the next step is to be welded in a jig. A jig aligns each

individual component with each other and is the only way to get an accurate end

result. All of our jigs are created using a genuine original door frame to

ensure each door we make is dimensionally correct to an original item. Using a

jig means each door comes out with the exact same level of accuracy as the one

made before it, ensuring the door for your Land Rover® fits correctly!

The next step after each door

frame is welded, even though we use a jig to align our parts for welding, each

frame is checked in critical dimensions to ensure each door meets our high

standards.

Before fitting the door skin, we

send every frame of to be hot dipped galvanised. Before doing so we prep each

door frame to ensure each threaded hole will not fill up with molten zinc so

you as the customer do not have to re-tap threaded holes making fitting the

doors so much easier!

Once the frames have come back

from the galvanisers, it is now time to fit the door skin. Due to the nature of

dipping a steel frame into a bath of molten zinc, it can leave some rough areas

on the frame. These is carefully prepped so that when the skin is fitted, no

lumps of zinc show through the skin.

Depending on the build

specification, we either fit an aluminium skin or a galvanised steel skin. Our

galvanised steels skins are electroplated so are perfectly smooth ready for

painting, just as with their aluminium counterparts. Before crimping the skin

to the frame, we use a Polyurethane sealant which seals between the frame and

skin. This helps to prevent the outer skin rubbing on the inner frame and also

stops rattling so the door sounds nice when it shuts, so it shuts with more of

a thud than a rattle. We use a combination of a skinning machine to crimp the

main parts of the skin to the frame and we then hand finish off any other areas

in the exact same way as was used on the production line.

As a final prep, when an

aluminium skin is fitted, we sand over the skin remove any high spots or minor

imperfections, so the skin is perfectly smooth and prepped ready to be painted.

The finished door is now ready to

packaged and sent out to anywhere in the world for its happy customer.